Top Features to Look for in a Modern Bitumen Melting System

GerryJarlشیئر کریں۔

In today’s fast-paced road construction industry, efficiency, safety, and cost-effectiveness are critical. Selecting the right bitumen melting system is no longer just about heating performance—modern projects demand more. Whether you’re a contractor working on highways, airports, or urban infrastructure, investing in the right equipment can significantly impact project speed, safety, and overall profitability.

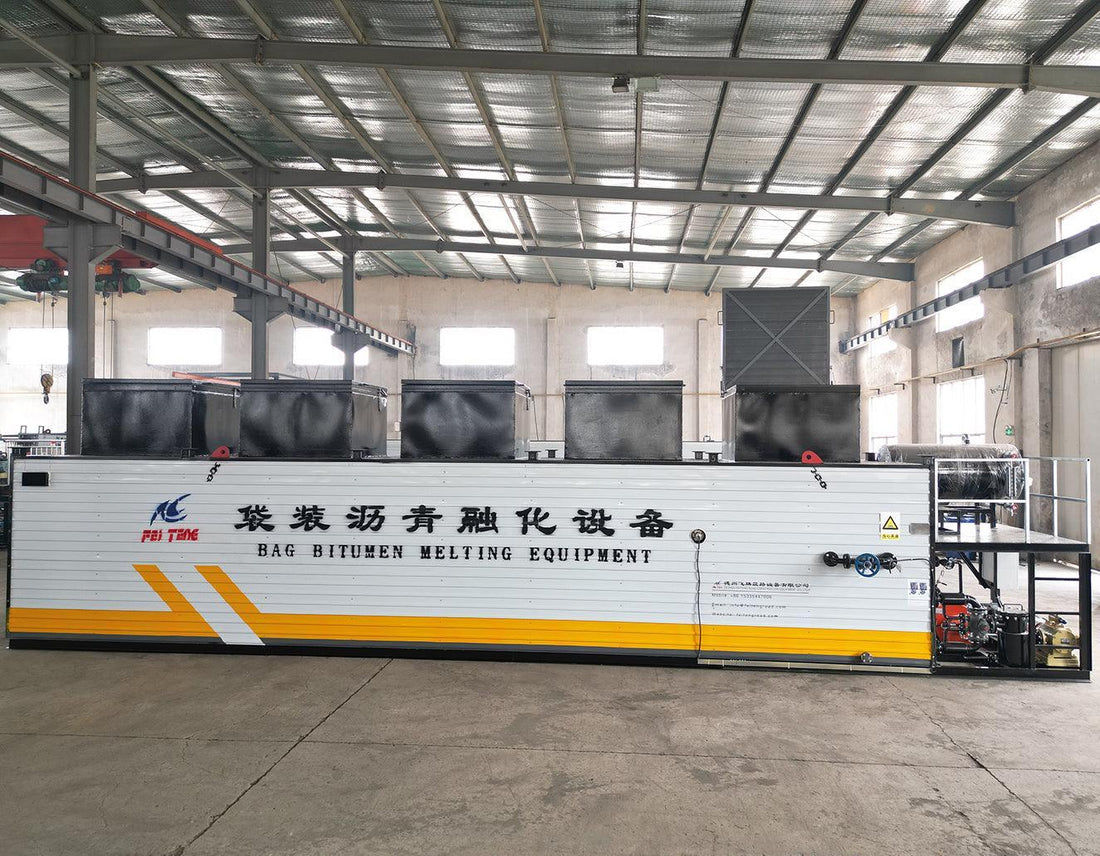

At Feiteng Road Construction Equipment Co., we’ve worked with professionals across 30+ countries, and here’s what we believe are the top features to look for when evaluating a modern bitumen melting system.

🔥 1. High Melting Efficiency with Continuous Output

Modern road projects can’t afford downtime. A high-performance system should offer:

-

Continuous melting of 4-8 tons/hour

-

Fast heat-up time (<2 hours for first melt)

-

Even heat distribution to avoid carbonization or overheating

Our YDLR Series Bitumen Melting Machines adopt thermal oil heating with double coil heat exchange zones, ensuring high efficiency and consistent output.

🔁 2. Integrated Thermal Oil Circulation

Heat consistency is the key to protecting the quality of bitumen. Look for:

-

Internal heating coil system

-

Integrated diesel or electric thermal oil boiler

-

Stable temperature control (±1°C)

An integrated design not only reduces pipeline heat loss but also simplifies the installation process and cuts overall operating costs.

🛠️ 3. Ease of Installation and Mobility

Contractors today need mobile flexibility. A good melting unit should offer:

-

Skid-mounted or container-type frame

-

Easy transport and setup on-site

-

Plug-and-play automation system

Feiteng’s containerized decanter systems allow easy deployment in remote locations, saving both time and money.

🧠 4. Advanced Automation & Control Systems

Manual monitoring is error-prone. Modern systems should feature:

-

Digital control panels with touch screen

-

Automatic temperature & level monitoring

-

Safety interlocks and fault alarms

This reduces operator error and ensures consistent production, particularly useful for night-shift or long-duration operations.

♻️ 5. Energy Efficiency & Heat Recovery

Energy costs are rising. Modern systems should be engineered for:

-

High fuel efficiency diesel burner or electric heating

-

Hot gas recycling systems

-

Optimized thermal insulation layers (e.g. Rock wool + stainless steel)

Feiteng systems offer up to 20% energy savings compared to conventional single-stage drum melters.

🔒 6. Built-in Safety Measures

Safety isn’t optional. Look for:

-

Explosion-proof electrical boxes

-

Over-temperature shutdowns

-

Bitumen overflow prevention systems

Our machines comply with CE standards and are designed for extreme weather—from -20°C to +50°C.

🧼 7. Low Maintenance Design

Downtime due to clogged valves or burnt bitumen reduces productivity. Choose:

-

Self-cleaning heating coils

-

Removable drum holders

-

Automatic slag discharge system

Feiteng’s low-maintenance philosophy means fewer stoppages and longer service life—ideal for high-volume operations.

🌎 8. Environmental Compliance

Eco-conscious construction is a growing trend. Choose systems that:

-

Comply with EU/US emissions standards

-

Feature closed-loop thermal oil systems

-

Minimize fume emissions and carbon residue

✅ Final Thoughts

Choosing a modern bitumen melting system is not just about heating—it’s about efficiency, safety, energy saving, and reliability. At Feiteng, we engineer our systems to meet the needs of today’s global contractors, offering customized solutions that help save time, reduce costs, and boost overall performance.

If you’re looking for a bitumen melter that works smarter—not just hotter—get in touch with our team today.

📌 Recommended Product: YDLR Series Bitumen Melting Machine

-

Output: 5–10 tons/h

-

Heating: Diesel-fired or electric thermal oil system

-

Containerized & modular design

-

CE Certified