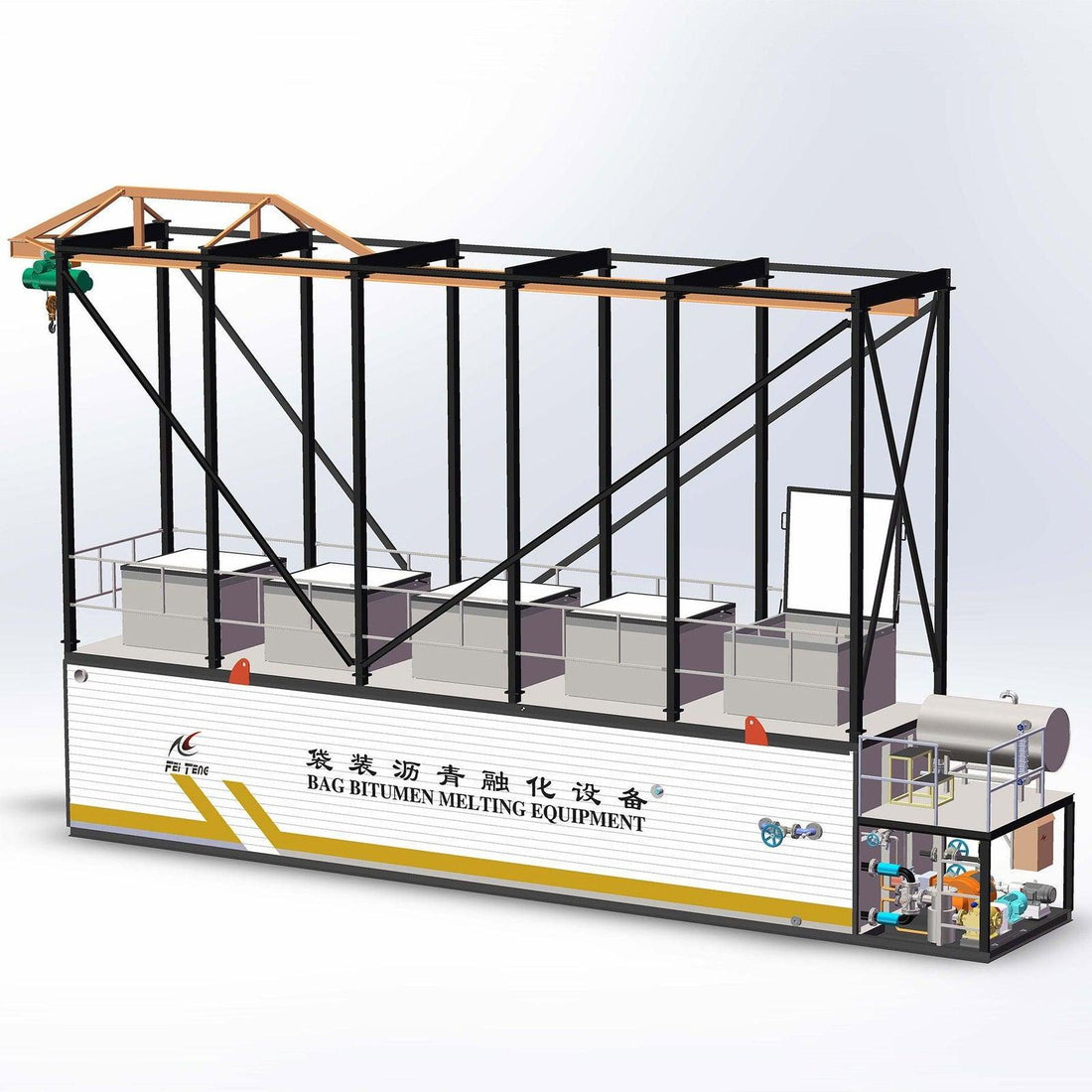

Bitumen Bag Decanter: The Smart Solution for Efficient Bitumen Melting

GerryJarlCompartilhar

In the ever-evolving world of road construction and infrastructure development, efficiency, flexibility, and environmental sustainability are more crucial than ever. As global demand for bitumen-based materials continues to rise, contractors and asphalt plant operators are looking for faster, safer, and more efficient methods of bitumen handling. Among the most promising technologies on the market today is the Bitumen Bag Decanter — a modern solution specifically designed to melt bitumen stored in plastic or bagged form.

This article introduces the working principles, structure, features, and advantages of the Bitumen Bag Decanter, helping you understand why it is the ideal equipment for high-performance road projects.

What Is a Bitumen Bag Decanter?

A Bitumen Bag Decanter is a specialized melting unit engineered to reliquefy bitumen that is stored and transported in plastic bags or soft containers. Unlike traditional drum decanters which are designed for steel-barreled bitumen, the bag decanter caters to low-cost, flexible packaging formats such as PE bags or jumbo bags commonly used in developing regions.

The unit uses thermal oil heating or direct heating systems to melt the bagged bitumen safely and quickly, transferring the liquid bitumen to storage tanks or mixing systems for further use.

Key Components of a Bitumen Bag Decanter

-

Feeding Chamber

The chamber is designed to accept 1-ton or smaller bitumen bags directly. A hydraulic lifting system or loading crane can be used to place bags into the chamber safely and efficiently. -

Heating System

Most decanters use thermal oil as the heat transfer medium, maintaining uniform temperatures throughout the melting chamber. Indirect heating helps prevent overheating or bitumen degradation. -

Melting Chamber & Grid

A heat-conductive steel grid or perforated platform is used to support the bitumen bags. As heat rises, the plastic melts and the bitumen flows down into a heated collecting tank. -

Bitumen Collecting Tank

The melted bitumen is collected in an insulated tank with an agitator to prevent settling or overheating. From here, bitumen can be pumped to an external tank or asphalt mixer. -

Bitumen Pumping System

A heat-traced bitumen pump transfers the liquid bitumen to storage or mixing equipment. The system ensures a continuous supply of bitumen with minimal manual handling.

Advantages of Using a Bitumen Bag Decanter

1. Environmentally Friendly Packaging

Bitumen bags are lightweight, recyclable, and easy to store. Unlike steel drums, they reduce transportation weight and environmental impact. The decanter system is designed to safely separate and remove melted plastic during the process.

2. Lower Transportation & Storage Costs

Bagged bitumen is more compact and stackable compared to bulky barrels. It can be shipped in containers or trucks with minimal packaging waste, saving up to 30% in transport costs.

3. Efficient and Continuous Operation

Modern bitumen bag decanters can handle 5–10 tons per hour, depending on the model. With automated feeding and temperature control, operations can run continuously without frequent manual intervention.

4. Safe and Clean Melting Process

The indirect heating method ensures that bitumen is melted evenly without burning. The sealed system minimizes emissions, spills, and fumes, creating a safer work environment for operators.

5. Versatility and Compact Design

Ideal for remote job sites or mobile asphalt mixing plants, bag decanters take up less space and require shorter installation times. They are compatible with various bag sizes and types.

Typical Applications

-

Remote construction sites where bulk bitumen delivery is impractical.

-

Developing countries or tropical climates where bitumen may soften during transport.

-

Containerized asphalt plants needing compact, mobile bitumen melting solutions.

-

Emergency road repairs that require quick setup and minimal manpower.

Whether you're paving rural roads in Africa or setting up a temporary asphalt plant in Southeast Asia, the Bitumen Bag Decanter offers unmatched convenience and cost savings.

Why Choose Feiteng’s Bitumen Bag Decanter?

At Dezhou Feiteng Road Construction Equipment Co., Ltd., we have over 18 years of experience in designing and manufacturing premium-grade bitumen equipment. Our bag decanter systems are:

-

Built with high-strength steel and anti-stick coatings for durability and ease of maintenance.

-

Integrated with PLC intelligent temperature controls for precise operation.

-

Customizable in size, layout, and heating capacity to meet your project needs.

-

Backed by global after-sales support and technical consultation.

Whether you need a 5 TPH bag decanter for small jobs or a custom-designed system for high-volume projects, Feiteng provides reliable solutions tailored to your business.

Final Thoughts

As the construction industry continues to embrace smart, eco-friendly practices, the Bitumen Bag Decanter stands out as a game-changer. It not only improves handling efficiency but also reduces operational costs and environmental footprint. If your projects involve remote site work, containerized plants, or international bitumen logistics, this equipment deserves your serious consideration.

Contact Feiteng today to learn more about our bitumen bag decanter models and how we can help you boost efficiency in every drop of bitumen you use.